Application

Mining Industry

- Ore Unloading

After mining operations, ore must be unloaded from transport trucks to designated stockyards or initial processing areas. Truck unloaders are capable of handling various types of ore, including iron, copper, and gold. These machines accommodate different ore sizes and weights, ensuring efficient unloading from the truck bed. - Tailings Unloading

During mineral processing, large volumes of tailings are produced and must be transported to tailings storage facilities for disposal or further processing. Truck unloaders facilitate the unloading of tailings from trucks into tailings ponds or repositories. Their precise control prevents spillage and uneven stacking, supporting environmentally responsible tailings management.

Construction Industry

- Sand and Gravel Unloading

The construction industry demands large volumes of aggregates. At sand and gravel yards, truck unloaders unload materials from arriving trucks either into storage piles or directly onto production lines—for example, into mixing stations for concrete production. Their fast discharge rate ensures timely supply for construction operations, improving material turnover efficiency. - Cement Unloading

Truck unloaders are also effective for unloading powdered cement at cement plants or distribution hubs. They discharge cement into silos or other storage systems, minimizing dust emissions and improving environmental safety during the unloading process.

Chemical Industry

- Raw Material Unloading

Chemical plants rely on bulk materials, such as powdered or granular feedstocks used in plastics production. Truck unloaders ensure accurate unloading of these materials into storage bins or directly into processing units, maintaining a continuous material supply. For volatile or hazardous materials, sealing systems and specialized unloading mechanisms help reduce environmental pollution and protect workers’ health. - Finished Product Handling

After production, chemical products must be transferred to warehouses or shipping zones. Truck unloaders unload finished goods from transport trucks to specific storage locations, facilitating inventory control and outbound logistics.

Port and Terminal Industry

- Bulk Cargo Unloading

At bulk cargo terminals, large volumes of materials such as coal and grain are transported by truck. Truck unloaders transfer these materials from trucks onto conveyor belts, which then feed ship loaders or warehouses. This ensures smooth integration between truck transport and terminal equipment. - Auxiliary Use in Container Terminals

While container terminals primarily handle containerized goods, truck unloaders are useful in special cases—for example, when offloading loose cargo from damaged containers or temporarily removing bulk materials during transshipment. They support efficient handling and minimize operational delays.

Advantages

Unloading Performance

- High Discharge Speed

Truck unloaders significantly reduce truck dwell time with adjustable unloading speeds based on material properties and truck capacity. For free-flowing materials like sand or gravel, they can unload several cubic meters per minute—far exceeding manual unloading speeds. - Continuous Operation

Engineered for continuous discharge, truck unloaders maintain smooth, uninterrupted operation. Their mechanical and power systems are designed to prevent jamming or operational stops during unloading.

High Adaptability

- Compatible with Various Materials

Truck unloaders handle a wide range of materials, including bulk solids (e.g., ores, coal, grain), powders (e.g., cement, flour), and granules (e.g., plastic pellets, fertilizers). Adjustable parameters like conveyor speed and scraper angle allow the equipment to accommodate different material properties such as size, moisture, and flowability. - Adaptable to Various Truck Types

These machines are designed to work with a variety of truck sizes and configurations—from small dump trucks to large heavy-duty haulers. Adjustable platform height and discharge chute dimensions ensure complete and smooth unloading from trucks of different dimensions.

Unloading Control

- Accurate Positioning

Equipped with advanced positioning and control systems, truck unloaders can discharge materials precisely to designated locations. Sensors detect the truck’s position relative to the discharge area, and the automated system adjusts the unloading mechanism accordingly. This ensures accurate placement—whether unloading into specific silos, ore piles, or warehouse bays—facilitating better material organization and storage. - Precise Discharge Volume Control

With integrated weighing systems such as belt scales, truck unloaders can accurately measure and control the amount of material discharged. Operators can preset target discharge volumes, and the system will automatically stop unloading once the required amount is reached—essential for industries like chemicals or construction where material dosing is critical.

Structural Stability

- Comprehensive Safety Features

Truck unloaders include multiple safety systems, such as guardrails around the discharge platform to prevent falls, emergency stop buttons for instant shutdown, and braking mechanisms to prevent truck movement during unloading, ensuring stable and secure operation. - Durable Structural Design

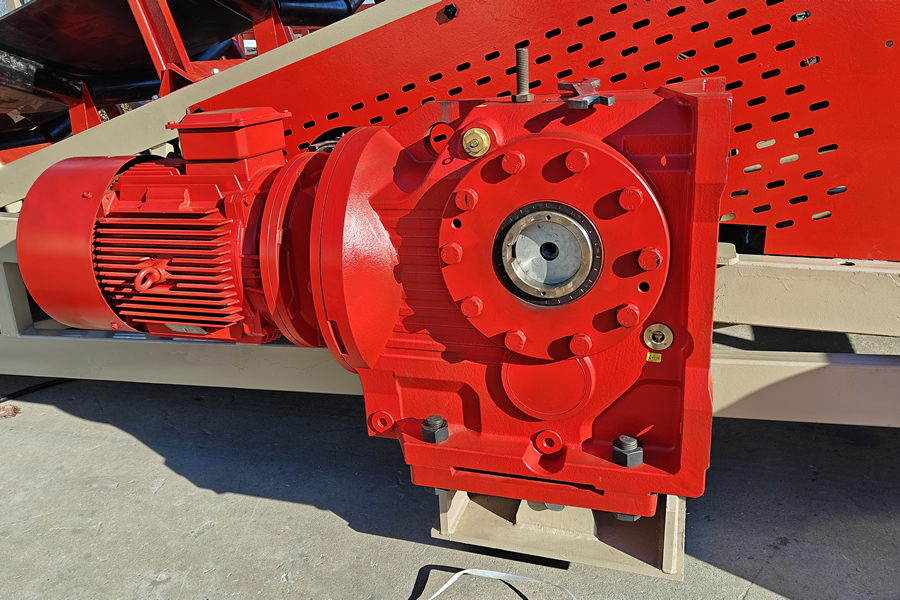

Constructed from high-strength steel and precision-engineered, truck unloaders are built to withstand continuous heavy-duty operation. Key components such as conveyors, scrapers, and drive gears are designed for long service life with minimal downtime, reducing failure rates and maintenance costs.

Environmental Sustainability

- Dust and Spillage Control

To minimize dust during unloading of powdered or fine materials, truck unloaders feature sealed discharge chutes and dust extraction systems. For instance, during cement unloading, sealed channels and vacuum units capture airborne dust, protecting both the environment and worker health. Well-designed unloading mechanisms also reduce material spillage, keeping work areas clean. - Energy-Efficient Operation

Equipped with variable frequency drive (VFD) motors, truck unloaders adjust power output based on real-time load demand. This reduces energy consumption during low-load or idle periods. Some models also incorporate smart power management for greater energy efficiency and lower operational costs.

Technical Specifications

| Truck Unloader | ||

| Hopper Volume | 0.5 m³- 5 m³ | Customizable |

| Unloading Speed | 1–10 m³/min (customizable) | |

| Discharge Accuracy | ±2% to ±5% | |

| Material Size Range | 5–500 mm | |

| Material Moisture | 0%–30% | |

| Platform Dimensions | 5–10 meters | |

| Hopper Volume | 1–20 m³ | |

| Installed Power | 585 kW | |

| Conveyor Belt Width | 0.5–2 meters | |

| Conveyor Speed | 0.5–3 m/s | |

| Motor Power | 1.5–15 kW | |