Application

Port Terminal Operations

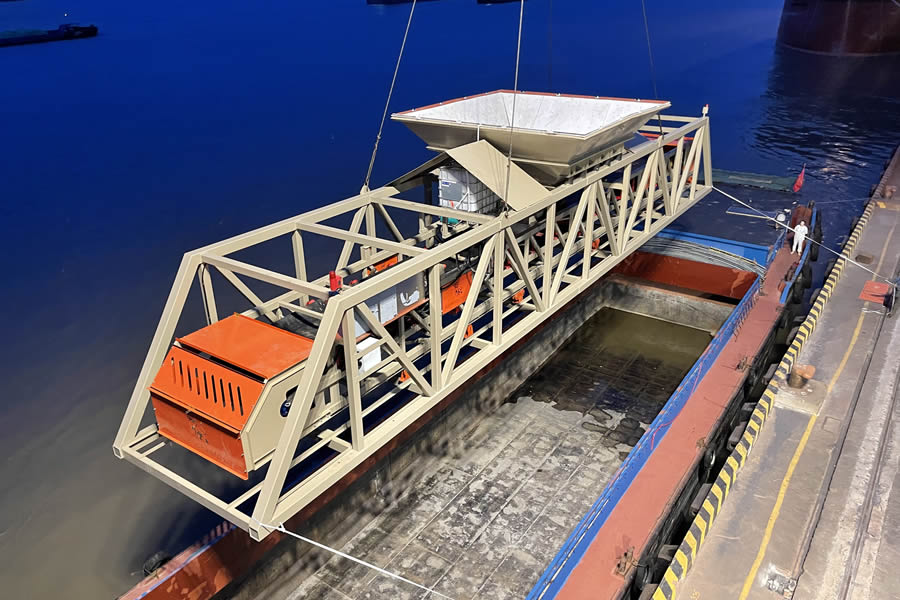

- Bulk Cargo Handling:

At port terminals, transshipment machines are used for the loading and unloading of bulk cargo such as coal, ore, and aggregates. For example, in coal transshipment operations where large bulk carriers cannot dock directly at the terminal, transshipment machines transfer coal from these vessels to smaller barges or directly onto shore-based conveyor systems. This process significantly increases port throughput efficiency. - Container Transfer:

At certain container terminals, transshipment machines are also employed for container transfer operations. When vessel berthing positions are less than ideal, they facilitate container transfer from one vessel to another or from a ship to the onshore container yard. This flexible transfer method improves terminal space utilization and optimizes handling workflows.

Inland Waterway Shipping

- Vessel-to-Vessel Cargo Transfer:

In inland shipping, due to factors such as channel conditions and vessel draft limits, cargo is frequently transferred between ships. Transshipment machines play a key role in this process. For example, along the Yangtze River, small barges can receive cargo from large dry bulk carriers via transshipment machines, then deliver it to various ports along the river. This segmented approach makes full use of waterway resources and improves cargo distribution efficiency. - Cargo Transshipment at River Ports:

River ports that lack comprehensive handling infrastructure rely on transshipment machines to transfer cargo from incoming vessels to suitable unloading equipment, or to redistribute cargo between different vessel types. This greatly improves cargo turnover efficiency at inland ports.

Offshore Oil and Gas Transport & Extraction

- FPSO Operations:

Floating Production Storage and Offloading (FPSO) units are critical in offshore oil extraction. Transshipment machines are used to transfer crude oil from FPSOs to shuttle tankers, facilitating offshore oil transportation. - Material Transfer Between Offshore Platforms:

In offshore oil and gas fields, multiple platforms are used, including drilling and production platforms. Transshipment machines are essential for transferring equipment, supplies, and crew provisions between these platforms. For example, drilling tools can be transferred from supply ships to drilling platforms, or food and essentials from living quarters to work platforms, ensuring smooth offshore operations.

Coastal Engineering & Offshore Wind Power Industry

- Material Transfer for Coastal Construction:

In large-scale coastal infrastructure projects such as port expansions and sea-crossing bridges, transshipment machines transport construction materials. For example, large quantities of steel and cement can be transferred from supply vessels to barges or to shoreline storage areas near construction sites. These machines adapt to complex marine conditions and tidal variations to ensure timely supply of construction materials. - Installation and Maintenance of Offshore Wind Equipment:

In offshore wind projects, transshipment machines assist in installing and maintaining wind power equipment. They handle the transfer of large wind turbine components such as towers, blades, and nacelles from transport ships to installation vessels or offshore platforms. During maintenance operations, they also transport damaged components back to shore for repair, ensuring the uninterrupted operation of offshore wind facilities.

Advantages

High Loading and Unloading Capacity

- Transshipment machines offer high efficiency in cargo handling. They can transfer materials between vessels or from a ship to shore-based facilities. For bulk cargo operations, their handling capacity can reach thousands of tons per hour, thanks to advanced mechanical and power systems. The conveying mechanisms operate at a stable speed, minimizing downtime during transfer and significantly improving cargo turnover. This reduces vessel berthing time and enhances operational efficiency for port and shipping companies.

High Flexibility

- Adaptability to Various Vessel Types:

Transshipment machines are capable of operating between different sizes and types of vessels, including large bulk carriers, container ships, and small barges. For example, when cargo needs to be transferred between a large container vessel and a small inland barge, the machine can adjust its working parameters—such as boom length and operating radius—to accommodate differences in vessel height, width, and cargo position, ensuring efficient cargo handling. - Operation in Diverse Work Environments:

These machines are suitable for use in a variety of environments, from the relatively stable conditions at port terminals to shallow inland waterways and challenging offshore environments. In rivers with fluctuating water levels and fast currents, their flexibility ensures continued performance. Offshore, even under adverse conditions such as waves and strong winds, transshipment machines maintain stability through specialized design and control systems.

Operational Control

- Transshipment machines are equipped with advanced control systems to manage cargo handling processes accurately. They can precisely control cargo positioning, handling speed, and volume. For example, in offshore oil transportation, they regulate the crude oil flow rate during transfers from FPSOs to shuttle tankers to prevent spillage. These control systems typically use automation technologies, integrating sensors to monitor cargo position and condition, and execute operations based on pre-programmed instructions. Operators can also make real-time adjustments via the control interface.

Cost and Resource Efficiency

- Reduced Infrastructure Investment:

In ports lacking deep-water berths or extensive dockside infrastructure, transshipment machines offer a cost-effective alternative. Instead of investing heavily in new terminal construction, these machines allow for flexible cargo transfers between vessels, reducing the demand for large-scale deep-water berths and cutting infrastructure costs. - Improved Vessel Utilization:

Transshipment machines enhance vessel utilization by enabling cargo transfers even when direct loading or unloading is not possible. This minimizes idle time caused by waiting for suitable conditions or berth availability, thereby reducing operating costs for shipping companies.

Technical Specifications

| Transshipment Machine | ||

| Hopper Volume | 0.5 m³- 5 m³ | Customizable |

| Rated Lifting Capacity | 60 tons (customizable) | |

| Max Working Radius | 40 meters | |

| Min Working Radius | 12 meters | |

| Lifting Height (Above Deck) | 15 meters | |

| Lifting Depth (Below Deck) | 12 meters | |

| Hoisting Speed | 65 meters/minute | |

| Installed Power | 585 kW | |

| Conveying Capacity | 2,268 tons/hour | |

| Rotation Angle | 50 degrees | |