Application Fields

1. Coal Industry

- In underground coal mines, the TDII roller belt conveyor is used to transport coal from the mining face to underground coal bunkers. Designed to perform in harsh environments with limited space and heavy dust, it ensures stable material flow. Its rollers provide strong belt support, allowing smooth coal transport, while the conveyor belt’s strength prevents breakage during heavy loads.

- In coal preparation plants, the conveyor is used to transport various grades of coal—such as clean coal, middlings, and gangue—to their respective storage bins or loading stations, facilitating downstream processing or transport.

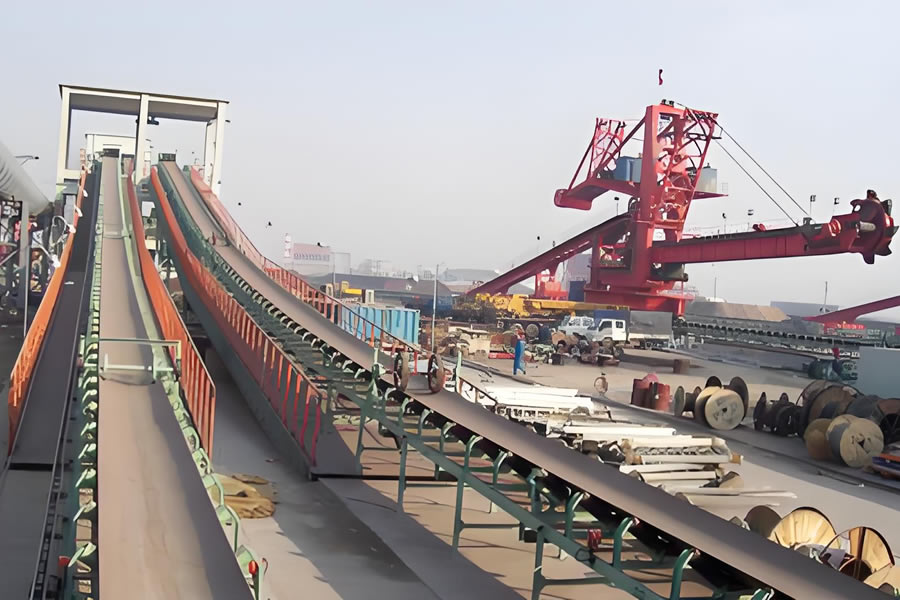

2. Ports and Terminals

- At bulk cargo terminals, the TDII conveyor is used for loading and unloading bulk materials such as ores, coal, and grains. For example, once ore is unloaded from ships, the conveyor can transport large volumes along specific routes to stockpiles. For grains, speed control and protective features prevent product damage or spillage during conveying.

- In container terminals, it can also transport auxiliary materials, such as components for conveyor-driven cargo handling equipment, ensuring smooth port operations.

3. Metallurgical Industry

- In ironmaking plants, the conveyor transports iron ore and coke to blast furnaces. Continuous raw material supply is critical for uninterrupted smelting, and the TDII conveyor offers stable delivery with adjustable capacity, operating reliably in high-temperature, high-dust environments.

- In steel plants, it transports steel billets—for instance, moving semi-finished billets from rolling mills to downstream workshops like heat treatment or finishing, supporting continuous production workflows.

4. Building Materials Industry

- In cement plants, the conveyor transports raw materials such as limestone, clay, and iron powder from mining or stockpiles to raw mills for grinding. It also handles finished cement, delivering it from silos to packaging areas or bulk loading stations.

- In ceramic factories, it transports both raw materials (e.g., clay, porcelain stone) and finished goods. It moves materials to shaping workshops and transfers fired ceramic products to packaging sections. Belt speed and tension can be adjusted to accommodate products of varying sizes and weights.

5. Chemical Industry

- The TDII roller belt conveyor is also used for transporting chemical raw materials and finished products. Based on the specific characteristics of the materials—such as corrosiveness or flammability—suitable belt materials and safety measures are implemented to ensure reliable and safe operation.

Advantages

High Conveying Capacity

- The TDII conveyor offers a wide range of conveying capacities—from a few dozen tons per hour up to several thousand—making it ideal for large-scale operations. Its belt width and speed can be customized. For example, in major coal mines, belts can reach widths of 1–2 meters and speeds of 3–5 m/s, delivering thousands of tons of coal per hour.

Wide Adaptability

- Terrain Adaptability: Suitable for flat or inclined conveying. The inclination angle can be tailored based on material characteristics (e.g., particle size, moisture, friction). For dry coal, the angle can reach 18–20°. In mountainous mining areas, it can move ore downhill from the mine to the processing plant, reducing transportation difficulty.

- Material Compatibility: Capable of handling a variety of materials—lumps (e.g., ores, coal), powders (e.g., cement, flour), and granules (e.g., grains, fertilizers). Belt tension, speed, and roller spacing can be adjusted for particle sizes from a few millimeters to several centimeters and densities ranging from lightweight grains to heavy metal ores.

Stable Operation

- Roller Support: Rollers play a key role in maintaining smooth operation. Evenly distributed beneath the belt, they prevent sagging and misalignment. Designed with rolling bearings, the friction between the belt and rollers is minimized, ensuring steady movement and accurate delivery over long durations.

- Drive System: Typically composed of a motor, reducer, and coupling. The reducer converts the motor’s rotation into a suitable speed for the belt. The system is designed for continuous, reliable operation, reducing downtime due to mechanical failures.

Simple Structure and Easy Maintenance

- Straightforward Design: Comprised of a belt, rollers, frame, drive system, and tensioning device. Compared to more complex systems like chain conveyors, its mechanical structure is simple, making it easier for operators to understand and maintain.

- Easy Replacement of Wear Parts: Rollers are wear-prone components. Thanks to their simple mounting system, damaged rollers can be quickly and easily replaced by maintenance personnel.

Environmental Performance

- Energy Efficiency: With a well-optimized drive system and operational parameters, energy consumption is reduced. Variable frequency drives (VFDs) allow the motor to adjust speed based on load demand, minimizing energy waste during low-load operation and significantly lowering operating costs.

- Dust & Pollution Control: When handling powdered materials such as cement or coal dust, the conveyor’s sealed design minimizes dust leakage. Its stable operation reduces spillage and material waste, thereby lowering environmental pollution.

Technical Specifications

| TDII Roller Belt Conveyor | ||

| Conveying Capacity | 10-3000t/h | Customizable |

| Belt Width | 0.8-2.5m/s | |

| Belt Speed | <30m | |

| Operating Temperature | – 25℃~40℃ | |

| Conveying Angle | 18-20° | |

| Roller Diameter | 89mm、108mm、133mm、159mm | |

| Power Supply Voltage | 220V、380V、450V、660V、690V AC | |