Application

Mining Industry

In underground coal mines, the TD75 belt conveyor is used to transport coal from the working face to underground coal bunkers or directly to the surface. Its strong conveying capacity significantly improves coal transportation efficiency. For example, in medium-sized coal mines, a proper layout of TD75 conveyors can achieve the continuous transport of several thousand tons of coal per day.

In metal mines (e.g., iron ore, copper ore) and non-metallic mines (e.g., limestone, gypsum), the conveyor transports ore from the mining site to beneficiation plants or stockpiles. It can handle a wide range of material sizes—from fine ore powders to large ore lumps.

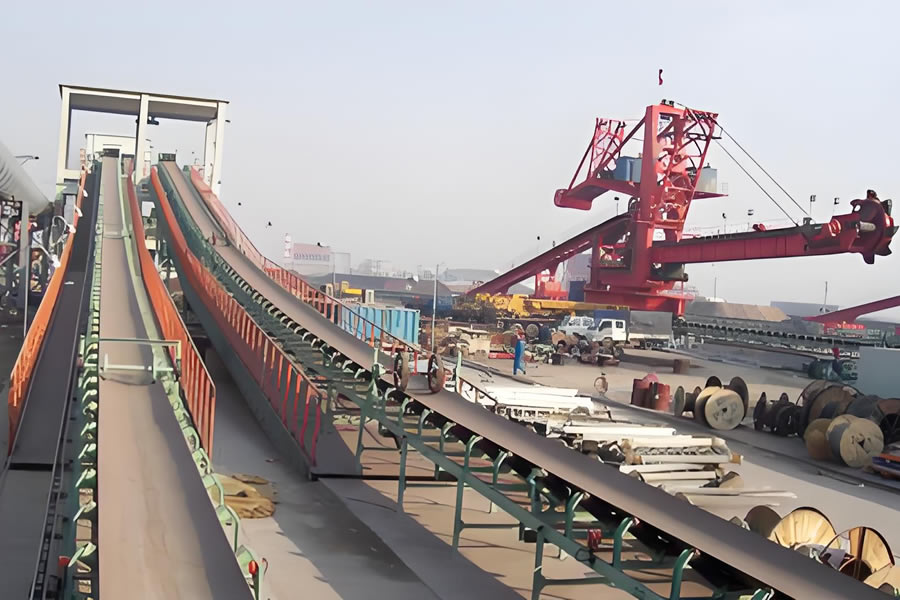

Ports and Terminals

The TD75 belt conveyor is used for loading and unloading bulk materials such as coal, ores, grain, and fertilizers. When unloading large bulk carriers, it can work in tandem with grab cranes to quickly transfer cargo to stockyards or warehouses.

During loading operations, it transfers goods from storage areas into ship holds, improving efficiency. Although container handling dominates modern ports, TD75 belt conveyors are also used in auxiliary areas, such as warehouses storing container fillers (e.g., wood chips, foam), to transport these materials.

Power Industry

In thermal power plants, the TD75 belt conveyor is a key system for transporting coal from the coal yard to the raw coal bunker of the boiler room, ensuring continuous power generation.

It is also used to transport ash generated from coal combustion to ash yards or treatment facilities for reuse, helping to solve ash disposal problems and reduce environmental pollution.

Building Materials Industry

During cement production, the TD75 belt conveyor transports raw materials such as limestone, clay, and iron ore to the raw mill and delivers finished cement to storage silos or packaging lines.

It enables efficient material flow across different production stages. It is also suitable for transporting ceramic raw materials like kaolin and quartz sand—from material reception and batching to the forming workshop—ensuring accurate and timely supply.

Grain Processing and Storage

At grain collection stations and large grain depots, the TD75 belt conveyor transports raw grains like rice, wheat, and corn from unloading points to silos, reducing handling loss and contamination.

In grain processing plants, it conveys materials between each production stage—from cleaning and de-stoning to grinding and packaging—ensuring smooth and continuous processing.

Advantages

Conveying Capacity and Efficiency

- High Throughput: Capable of handling large-scale material transport. Various combinations of belt width and speed meet different capacity needs—from small-scale to over 1,000 tons per hour.

- Long-Distance Transport: Enables long-distance conveying, reducing intermediate transfer points and minimizing material loss and costs—ideal for mines, ports, and other large-scale sites.

- Continuous Operation: Designed for stable, uninterrupted performance, making it suitable for industries requiring high production continuity, such as chemical and power sectors.

Structure and Maintenance

- Simple Structure: Consists of a conveyor belt, drive pulley, return pulley, rollers, frame, and drive unit—compact and easy to install, allowing for quick setup and commissioning.

- Easy Maintenance: Equipped with standardized, interchangeable parts for convenient replacement. Routine maintenance includes belt inspection, roller replacement, pulley cleaning, and lubrication—easy and cost-effective.

- Low Energy Consumption: Due to low friction and high transmission efficiency, energy consumption is minimal, lowering operating costs and saving energy over time.

Transport Quality and Adaptability

- Smooth Conveying: Little relative motion between materials and the belt prevents damage—ideal for fragile or easily worn materials such as grains and glass products.

- Low Noise: Operates quietly, minimizing disturbance in noise-sensitive environments.

- Strong Adaptability: Can be customized for resistance to heat, cold, water, corrosion, explosion, and fire. Operates reliably in harsh environments, including high temperatures, cold, humidity, and corrosive conditions.

Operation and Control

- Automation & Centralized Control: Easily integrates with other systems for automated operation and centralized management—improving productivity and reducing human error, ideal for large-scale, automated production lines.

- Multi-Point Loading and Discharging: Supports multiple loading and unloading points along the conveyor, enhancing flexibility in material distribution and meeting complex production needs.

Technical Specifications

| TD75 Type Belt Conveyor | ||

| Conveying Capacity | 40-2000t/h | Customizable |

| Belt Speed | 0.8、1.0、1.25、1.6、2.0、2.5、3.15、4.0m/s | |

| Loading Capacity | 1.0 ton/meter | |

| Belt Width | 500、800、1000、1200、1400mm | |

| Max Conveyor Incline Angle | B≤60 | |

| Motor Power | 1.5-200Kw共12种 | |

| Power Supply Voltage | 220V、380V、450V、660V、690V AC | |

| Operating Temperature | – 25℃~40℃ | |

| Inclination Range | 30-90° | |