Application

Mining Industry

- Coal Sector: Underground, the TD roller belt conveyor can steadily transport coal through complex terrains to coal bunkers or transfer points. On the surface, it moves coal to processing plants or loading stations.

- Ore Sector: During mining operations, it transports ore from extraction points to stockyards or beneficiation plants. Inside the beneficiation plant, it conveys processed concentrates or tailings.

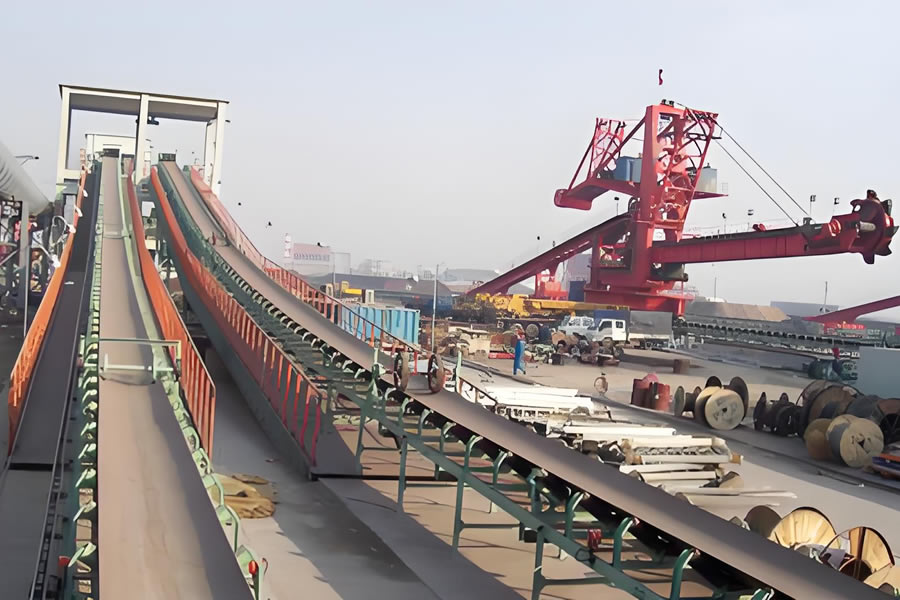

Ports and Terminals

Used for bulk cargo unloading and ship loading operations. It also facilitates bulk cargo transfer between different port areas, such as between stockyards or from stockyards to processing workshops.

Power Industry

- Thermal Power: Transports coal from coal yards to raw coal bunkers in boiler rooms, ensuring stable power generation. It also conveys ash from the boiler room to ash disposal sites or recycling facilities.

Building Materials Industry

- Cement Production: Delivers raw materials like limestone to the raw mill and transports finished cement to silos or packaging workshops.

Advantages

Conveying Performance

- High Capacity: Handles hundreds to thousands of tons per hour with continuous operation, suitable for large-scale conveying needs in mining, ports, and more.

- Adjustable Speed: Conveyor speed can be flexibly adjusted based on material characteristics and conveying requirements—slower for fragile materials, faster for bulkier or tougher ones.

Equipment Performance

- Robust and Stable Structure: Rollers provide uniform support to the belt. The frame offers high strength and rigidity, allowing it to bear heavy materials without belt sagging, ensuring long-term stable operation and reduced maintenance.

- Low Energy Consumption: The well-designed power transmission system and rollers minimize friction resistance, lowering energy use and saving operational costs over time.

Material Adaptability

- Versatile Material Handling: Capable of conveying various materials with different particle sizes and viscosities. Can be customized with protective features for high-temperature or corrosive materials—e.g., wear-resistant belts and heat-insulated rollers for hot cement clinker.

- Minimal Material Loss: Stable belt operation prevents spillage, ideal for transporting valuable or environmentally sensitive materials.

Maintenance and Operation

- Easy Maintenance: Rollers and other components are easy to inspect and replace. The conveyor belt is also easy to repair, with straightforward routine cleaning and lubrication procedures.

- Simple and Flexible Operation: Operable by staff with minimal training. Functions such as start/stop and speed adjustment can be managed via a control system. The system supports multi-point loading and unloading, offering flexible material handling options.

Technical Specifications

| TD Roller Belt Conveyor | ||

| Conveying Capacity | 10-3000t/h | Customizable |

| Conveying Speed | 0.8-2.5m/s | |

| Stacking Height | <30m | |

| Belt Width | 300-1400mm | |

| Conveying Distance | 10-80m | |

| Motor Power | 55-220kw | |

| Power Supply Voltage | 220V、380V、450V、660V、690V AC | |

| Operating Temperature | – 25℃~40℃ | |

| Inclination Range | 18-20° | |