Applications

Mining Industry

- Ore Extraction: Used to transport mined ore from the excavation site to processing plants or stockpiles. In open-pit coal mining, it efficiently conveys coal to the coal preparation plant.

- Ore Processing: Transports crushed and screened ore particles to different processing stages such as grinding, flotation, and magnetic separation.

Port Terminals

- Material Handling: Transfers bulk materials such as sand and gravel from ships to stockyards or vice versa.

- Port Construction: Delivers construction materials like sand and gravel to the job site for port foundation filling and structural casting.

Logistics and Warehousing

- Goods Transport: Moves goods from warehouse entry points to storage areas, or from storage to dispatch.

- Sorting Systems: Works in conjunction with automated sorting systems to efficiently direct goods to the correct storage or shipping points.

Building Materials Industry

- Tile Production: Transports tile blanks to drying kilns or dried tiles to glazing, printing, and firing processes. Operates effectively in high-temperature, dusty environments.

- Glass Manufacturing: Conveys raw materials to melting furnaces and molten glass to forming equipment. Conveying speed and direction can be adjusted as per process requirements.

Features

High Conveying Capacity

- Engineered to handle heavy materials. Reinforced sidewalls and adjustable spacing allow for transport of items of various sizes and weights.

- Conveying speeds are adjustable (typically 0.5–5 m/s), supporting demanding material flow needs.

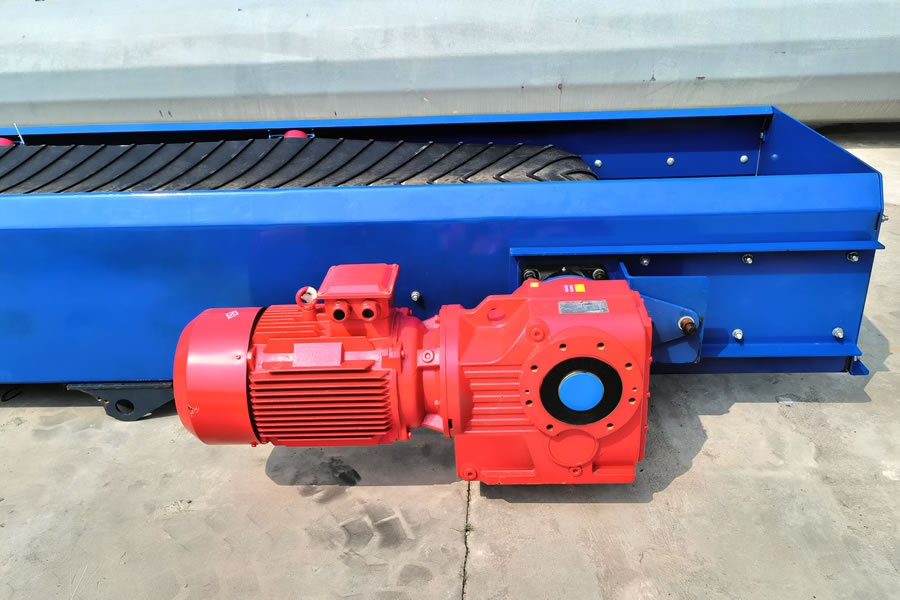

Smooth Operation

- Tight, stable connection between belt and drive reduces vibration and noise.

- Flat belt surface and ribbed design stabilize material during transport, minimizing spillage and accumulation.

Excellent Adaptability

- Customizable sidewall shapes, spacing, heights, belt materials, and widths to suit various material properties.

- Operates reliably in harsh environments including high/low temperatures, humidity, and dust.

Low Maintenance

- Simple structure made up of belt, sidewalls, drive system, and support frames, with fewer parts reducing breakdown risks.

- Easy replacement of wear parts like belts and sidewalls lowers repair time and cost.

- Lubrication and sealing systems reduce wear and extend service life.

High Automation

- Seamlessly integrates with automated systems for material transport, sorting, and distribution.

- Advanced control systems enable remote monitoring, real-time status tracking, and immediate fault detection.

| Ribbed Rubber Belt Conveyor | ||

| Conveying Capacity | Small: 0–50 t/h, Medium: 50–200 t/h, Large: 2000+ t/h | Customizable |

| Conveying Speed | 0.5m/min-15m/min | |

| Belt Widths | 500mm、600mm、650mm、800mm、1000mm、1200mm、1400mm | |

| Conveying Distance | 10m、20m、30m、50m | |

| Motor Power | 1.5-180kW | |

| Power Supply Voltage | 220V、380V、450V、660V、690V AC | |

| Operating Temperature | – 20℃~50℃ | |

| Inclination Angle | 30°-35° | |

| Bending Radius | 5m-8m | |