Applications

1. Industrial Sector

In the industrial sector, conveyor impact beds are widely applied in continuous bulk material handling operations. For instance, in cement plants, where materials are often large and dropped from considerable heights, traditional conveyor belts are prone to damage over time, resulting in high maintenance costs. The use of heavy-duty impact beds significantly enhances the belt’s durability thanks to their superior load-bearing and impact-absorbing performance. Statistics from a major cement plant show that after implementing heavy-duty impact beds, conveyor belt lifespan more than doubled, greatly reducing maintenance costs and downtime.

Industries such as steel, coal, and chemicals also face impact-related challenges in material transport. Impact beds effectively alleviate the load on conveyor belts, ensuring more uniform force distribution and lower maintenance requirements, thereby boosting conveying efficiency. For example, in coal mining operations, light-duty impact beds are ideal for handling loose raw coal—protecting the belts while minimizing material loss and improving productivity.

2. Logistics Sector

In logistics, impact beds play a critical role, especially as automated warehousing and sorting systems become increasingly common. Conveyor belts serve as essential links within these systems, and impact beds help absorb shock from falling parcels, reducing belt wear caused by frequent impacts. This is essential for maintaining consistent and stable operations in high-throughput environments.

In e-commerce and express delivery industries where massive volumes of parcels are handled daily, impact beds help minimize equipment failures and downtime caused by impact damage. Data from a major e-commerce warehouse revealed that introducing impact beds reduced conveyor maintenance costs by 30% and improved operational efficiency by 15%.

3. Agricultural Sector

While not as widely used as in industrial or logistics sectors, conveyor impact beds also serve vital functions in specific agricultural scenarios. For example, in livestock farms, conveyor belts are used for feed delivery, animal transport, and waste handling. When handling heavy materials such as feed or animal carcasses, impact beds absorb the falling impact, helping to prevent belt damage and extend equipment service life.

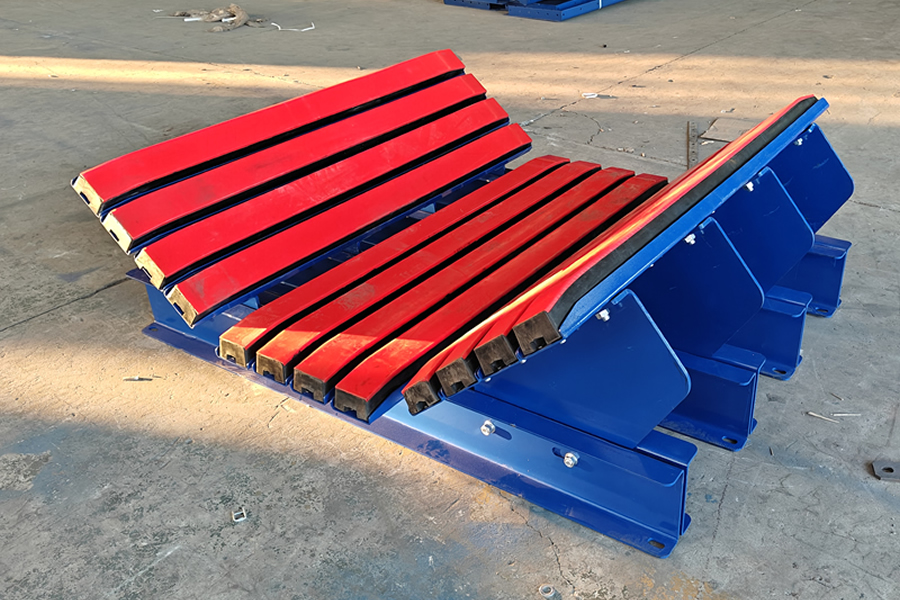

Features

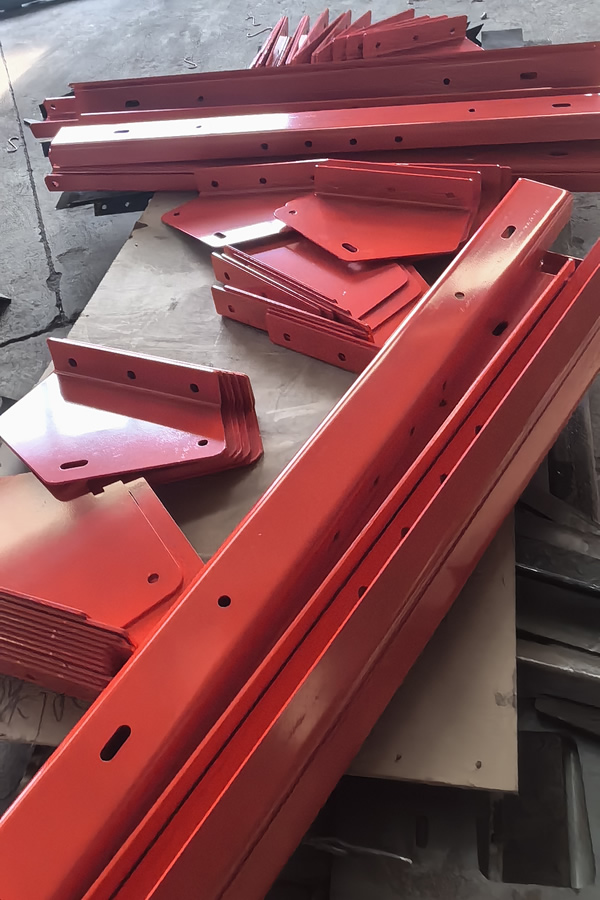

Modular steel base structure enables fast and easy installation or replacement.

Full-surface contact between the impact bar and belt reduces localized wear.

Even force distribution at drop points significantly lowers routine maintenance and repair costs.

Prevents material spillage and dust leakage caused by uneven belt tension.

Smooth surface design minimizes friction during belt operation.

Arc-shaped surface ensures smooth and stable belt movement.

High-resilience rubber layer effectively absorbs material impact.

Technical Specifications

| Impact Bed | |||

| Belt Width | 650~2400mm | ||

| Impact Bar Length | 1200mm、1400mm、1500mm、1600mm、1800mm、2000mm | Customizable | |

| Trough Angle Options | 25、35、45 | ||

| Operating Temperature | -30\~80℃ | ||

| Conveying Speed: | v≥4.5m/s,I≥6000t/h | ||

| Capacity | h≥3m | ||