Application:

Coal Industry

- Underground Mines: Accurately distribute coal into different silos in limited space.

- Surface Coal Yards: Discharge coal into specific areas based on type and grade.

Port Terminals

- Bulk Terminals: Distribute bulk materials to different storage yards or warehouses to maximize space utilization.

- Container Terminals (bulk section): Transfer bulk materials from containers to reduce backlog.

Power Industry

- Thermal Power Plants: Distribute coal to different bunkers based on boiler requirements.

Metallurgy Industry

- Iron and Steel Plants: Distribute raw materials like iron ore and coke to blast furnaces or steelmaking furnaces.

- Non-Ferrous Smelting Plants: Deliver materials such as bauxite and copper ore to specific workshops.

Building Materials Industry

- Cement Plants: Allocate raw materials like limestone to production workshops or raw material storage areas.

- Glass Factories: Accurately unload quartz sand and other materials to designated silos or workshops.

Chemical Industry

- Fertilizer Plants: Distribute raw materials as required by the production process.

- Other Chemical Plants: Allocate raw materials, intermediates, and final products to respective production stages.

Grain Industry

- Grain Storage: Distribute grain into different silos based on type or quality.

- Grain Processing Plants: Deliver grain to processing workshops, packaging areas, or finished product warehouses.

Advantages:

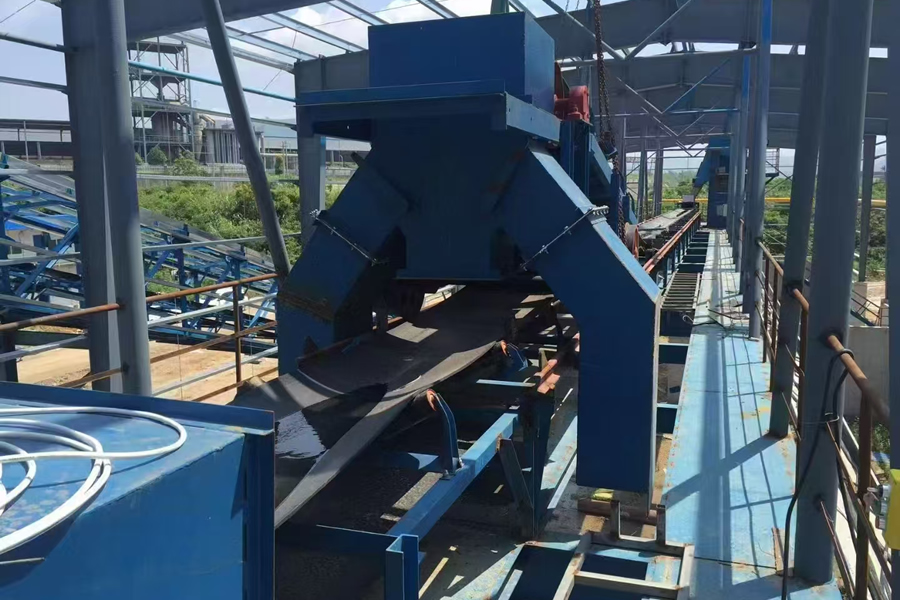

- Flexible and Accurate Discharging: The tripper car moves along the belt conveyor rail, enabling precise discharging at different positions, ideal for allocating materials across various zones, such as specific silos in large warehouses.

- Continuous Operation: Works in sync with the belt conveyor for uninterrupted transport and discharging, significantly improving productivity. For example, in ports, bulk materials can be efficiently distributed to various storage yards.

- Easy Operation: Simple control system via local console or remote control reduces operator workload and increases efficiency.

- Strong Adaptability: Suitable for various materials like coal, ore, grain, and performs reliably in different environments such as high-temperature steel mills or humid underground coal mines.

- Easy Installation and Maintenance: Simple structure allows for easy setup and compact footprint. Maintenance is straightforward, with convenient parts replacement and low maintenance costs.

- High Automation: Can be integrated with automated control systems to achieve automatic positioning and discharging. Sensors and preset programs ensure fully automated operation.

Technical Specifications

| Belt Conveyor Tripper Car | ||

| Light-Duty Tripper Car | Customizable | |

| Bulk Density | ≤1600 kg/m³ | |

| Common Belt Widths | 500~1400mm | |

| Other Belt Widths | Customizable | |

| Heavy-Duty Tripper Car | ||

| Bulk Density | >1600kg/m³ | |

| Common Belt Widths | 800~1400mm | |

| Other Belt Widths | Customizable | |